Introduction

Laser beam splitter is a typical diffractive optical element. It divides an incident laser beam into multiple laser beams with uniform intensity distribution through diffraction. It has important applications in many optical fields.

In special cases, the laser beam splitting DOE should not only meet the requirements of high diffraction efficiency and high uniformity, but also be able to achieve large-angle beam splitting.

According to the theory of diffractive optics, to increase the diffraction angle, the period of the split beam DOE must be reduced. The decrease of DOE period will also lead to the decrease of approximation accuracy, especially in the calculation of scalar diffraction theory method, this effect is significant, so the vector design method must be introduced. At the same time, the requirements of the processing technology have increased sharply due to the reduction of the DOE cycle. If the limitations of processing equipment and processing errors cannot be taken into account in the design and calculation process, it will bring about a series of problems such as low diffraction efficiency, uneven beam splitting, etc. extremely low.

In practical large-scale applications, binary phase DOE is mostly used, and the master is made by photolithography, and then mass-produced by UV transfer printing, nano-imprinting and other series of processes. This method has low cost, but poor accuracy. in consumer products.

High-precision industrial applications generally use multi-step phase DOE, which can realize large-angle laser beam splitting. The multi-step DOE is a periodic binary optical element, each period is composed of multiple phase units, and these phase units form a step-like distribution. The uniformity accuracy can be controlled within 5%, and it has greater compatibility with processing error requirements. This model must use a semiconductor etching process and be produced by specialized semiconductor chip wafer processing manufacturers. The unit price is cheap in ultra-large batch production, but the cost is very high in small-scale production.

UPOLabs based on the SLM phase research platform, which integrates the domestic senior diffraction element design team and semiconductor etching processing service providers, integrates the processing technology and design calculation into a closed-loop chain technical service, and provides various research and industrial customers. beam device.

Application Scenarios

Small-angle beam splitting (<15°) is usually used in the field of high-power laser processing.The application scenarios such as scribing and drilling are widely used, and high diffraction efficiency is required. After coating, it can achieve more than 90% energy efficiency, and non-uniformity < 5%.

Large-angle beam splitting (<50°) is usually applied to specific scenes, and is currently mainly used in the field of multi-line lasers as the core component of machine vision light sources.

How to buy

The price and processing cycle of laser beam splitting devices are closely related to user needs. Please be sure to clarify the index parameters. If you do not know the specific parameters, you can consult UPOLabs technicians.

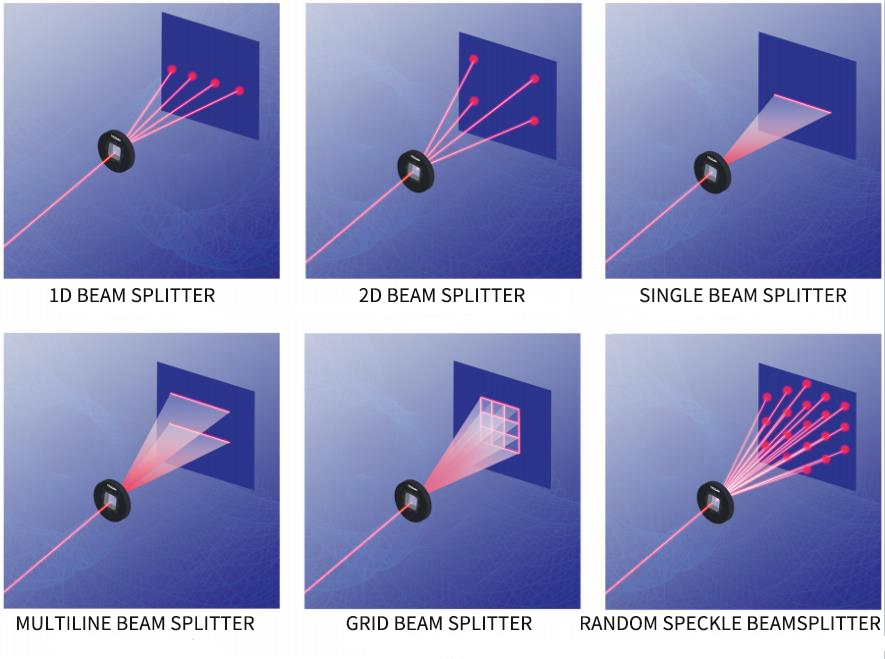

Beam Splitter Type

Beam splitter Standard List

| 1D Beam Splitter | |||

| Type | Wavelength | Number of beam splits | Angle |

| 450-1*3-9 | 450nm | 1*3 | 9 |

| 450-1*3-15 | 450nm | 1*3 | 15 |

| 450-1*5-14 | 450nm | 1*5 | 14 |

| 450-1*7-20 | 450nm | 1*7 | 20 |

| 450-1*11-30 | 450nm | 1*11 | 30 |

| 450-1*11-35 | 450nm | 1*11 | 35 |

| 450-1*13-38 | 450nm | 1*13 | 38 |

| 450-1*15-36 | 450nm | 1*15 | 36 |

| 450-1*17-40 | 450nm | 1*17 | 40 |

| 450-1*25-18 | 450nm | 1*25 | 18 |

| 450-1*49-23 | 450nm | 1*49 | 23 |

| 450-1*99-45 | 450nm | 1*99 | 45 |

| 450-1*101-15 | 450nm | 1*101 | 15 |

| 650-1*3-9 | 650nm | 1*3 | 9 |

| 650-1*3-15 | 650nm | 1*3 | 15 |

| 650-1*5-19 | 650nm | 1*5 | 19 |

| 650-1*7-23 | 650nm | 1*7 | 23 |

| 650-1*7-28 | 650nm | 1*7 | 28 |

| 650-1*7-50 | 650nm | 1*7 | 50 |

| 650-1*9-30 | 650nm | 1*9 | 30 |

| 650-1*9-37 | 650nm | 1*9 | 37 |

| 650-1*11-30 | 650nm | 1*11 | 30 |

| 650-1*13-38 | 650nm | 1*13 | 38 |

| 650-1*25-36 | 650nm | 1*25 | 36 |

| 850-1*11-30 | 850nm | 1*11 | 30 |

| 905-1*5-12 | 905nm | 1*5 | 12 |

| 905-1*32-25 | 905nm | 1*32 | 25 |

| 1064-1*3-0.32 | 1064nm | 1*3 | 0.32 |

| 1064-1*4-0.43 | 1064nm | 1*4 | 0.43 |

| 1064-1*4-5.39 | 1064nm | 1*4 | 5.39 |

| 1064-1*23-10.8 | 1064nm | 1*23 | 10.8 |

| 1064-1*23-3.23 | 1064nm | 1*23 | 3.23 |

| 1550-1*19-18 | 1550nm | 1*19 | 18 |

| 2D Beam Splitter | |||

| Type | Wavelength | Number of beam splits | Angle |

| 450-11*11-53 | 450nm | 11*11 | 53 |

| 525-5*5-7.5 | 525nm | 5*5 | 7.5 |

| 532-5*5-60 | 532nm | 5*5 | 60 |

| 532-7*7-6.8 | 532nm | 7*7 | 6.8 |

| 532-7*7-11 | 532nm | 7*7 | 11 |

| 532*8*8*3.51 | 532nm | 8*8 | 3.51 |

| 532-9*9-50 | 532nm | 9*9 | 50 |

| 532-11*11-50 | 532nm | 11*11 | 50 |

| 532-11*11-64 | 532nm | 11*11 | 64 |

| 532-17*17-60 | 532nm | 17*17 | 60 |

| 532-19-11 | 532nm | 19 | 11 |

| 532-61-11 | 532nm | 61 | 11 |

| 565-2*2-5.4 | 565nm | 2*2 | 5.4 |

| 650-15*15-8 | 650nm | 15*15 | 8 |

| 650-17*17-60 | 650nm | 17*17 | 60 |

| 650-21*21-30 | 650nm | 21*21 | 30 |

| 694-15*15-7.5 | 694nm | 15*15 | 7.5 |

| 850-65*65-10 | 850nm | 65*65 | 10 |

| 850-151*47-70*49 | 850nm | 151*47 | 70*49 |

| 980-9*9-11 | 980nm | 9*9 | 11 |

| 1064-5*5-11 | 1064nm | 5*5 | 11 |

| 1064-7*7-5.7 | 1064nm | 7*7 | 5.7 |

| 1064-7*7-11 | 1064nm | 7*7 | 11 |

| 1064-8*8-3.51 | 1064nm | 8*8 | 3.51 |

| 1064-8*8-11 | 1064nm | 8*8 | 11 |

| 1064-9*9-5.6 | 1064nm | 9*9 | 5.6 |

| 1064-9*9-8 | 1064nm | 9*9 | 8 |

| 1064-9*9-11 | 1064nm | 9*9 | 11 |

| 1064-7-11 | 1064nm | 7 | 11 |

| 1064-19-11 | 1064nm | 19 | 11 |

| 1064-37-11 | 1064nm | 37 | 11 |

| 1064-61-11 | 1064nm | 61 | 11 |

| 1064-61-16 | 1064nm | 61 | 16 |

| 2940-9*9-11 | 2960nm | 9*9 | 11 |

| 9600-9*9-11 | 9600nm | 9*9 | 11 |

| 10600-5*5-5.7 | 10600nm | 5*5 | 5.7 |

| 10600-7*7-11 | 10600nm | 7*7 | 11 |

| 10600-9*9-11 | 10600nm | 9*9 | 11 |